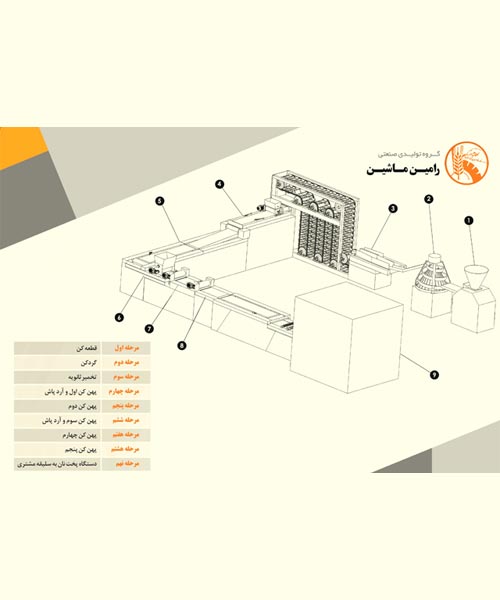

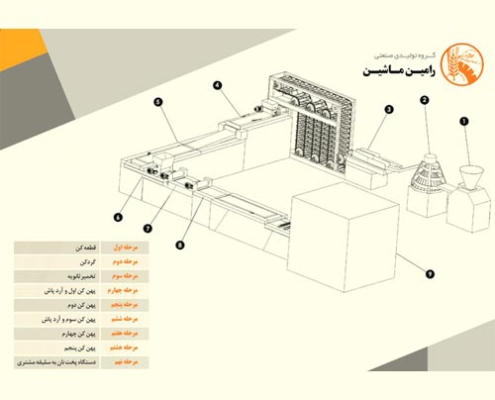

Details Taftoon bread line

The stages of the semi-industrial taftoon bread production line

1. The prepared dough (fermented) is transported to the hammer by the lift.

2. The paste is proportional to the operator’s view of the desired weight of the piece.

3. The parts of the dough are transferred to the rotary device and transferred to the fermentation device by the ducts of the guide to the bar setting (the number of petrols can be changed according to the consumer’s order of 140-1,600)

4. After secondary fermentation, the chains are inserted into the first platinum by the conductive bushings, and then rounded up by four rollers in proportion to the weight and thickness desired in several steps.

5. After complete expansion by the transmitter, it is ready to be coated in four stages of nailing (in two steps), sesame seeds and finally by nozzles.

6. At the last stage, the bread is bathed in 2 bands or 6 bands for three minutes or more.

7. Bread is cooled to the desired temperature on the cooling strip.

8. Bread is fitted with an automatic sealing machine.

Features of the fermentation machine

The number of petrols is from 2 to 4 and more tailored to the customer’s order

Capacity 140 to 1600 chin

The walls of the device are unbreakable

The fermentation time in the secondary fermentation device is adjustable from 10 to 30 minutes.

Features of the production line

All parts are made of stainless steel.

The tapes used in this line of food strips (with the universal standard).